Easy to Assemble

To build the model you only need some basic tools such as a screwdriver, a sharp knife, soldering iron and most importantly – a good mood.

Cheap and fast repairs

Did you break something? Don’t worry, you’ll have a reprinted spare part in no time. Then loosen a few screws and replace the damaged parts. And – drive again immediately!

3d print maximum, buy minimum

“Don’t buy parts – just print them, nearly all!” You print most parts starting with bodywork, complete chassis and even cardan joints and gearbox. Buy just motor, radio control electronics, tires and shocks/springs – and you are ready for ride.

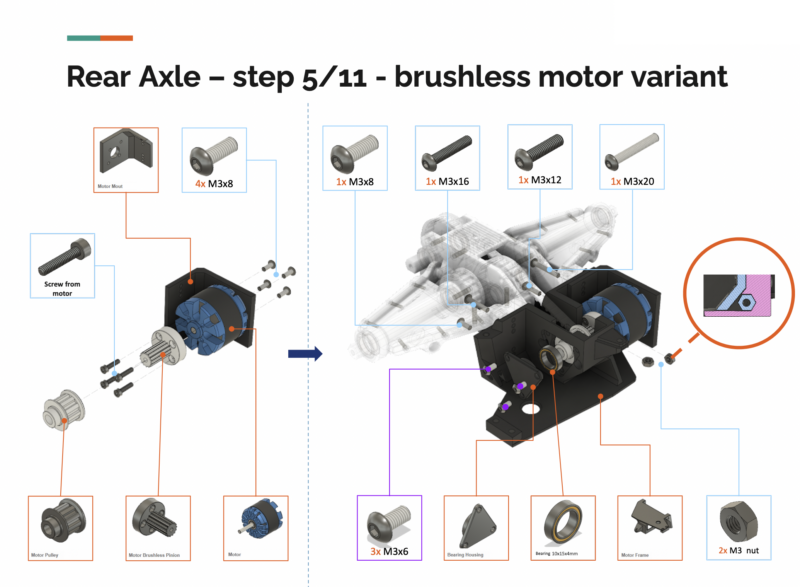

Step-by-step User Guide

Comprehensive Build Guide is available for free to anyone – lets go through before you buy the model. Build Guide include a complete bill of materials and links for online stores, when you can purchase non-printable parts.

“Build when you print” – you get not only the ready-made print plates but also the time-effective print sequence, so you can continue assembling while you printing and do not need to wait for the part you need.

Build Guide available here

List of non-printable parts is here

- 3D Sets BeltDrive – the transmission solution is durable, simple, and quiet because it uses timing belts.

- Differential – 3D Sets developed unique design of opened differential for best on-road capabilities. The differential is integrated right into the BeltDrive pulley and its special design doesn’t require any metal shafts or other tiny parts – everything is done using standard bearings, used in every 3D Sets model.

- Replaceable Windscreen – this model is a convertible and maybe you will break the windscreen frame someday – rollovers may happen during careless riding. But don’t worry: the windscreen assembly can be easily replaced as it’s not a part of the bodywork!

- HD Surface Details – this technique is used for incredibly fine surface structures of the folded roof and seats.

- Easy maintenance – the front and rear axles are attached with just a few screws and can be very easily removed from the model. An integral part of the rear axle is the transmission with engine and ESC – the entire drive system can be removed from the body in one movement.

- Easy-to-disassemble – Metal nuts are now embedded for repeatedly disassembled or stressed joints. Removing the axles is now much more convenient.

- Double Wishbone suspension – independently suspended front axle wheels with sophisticated wheel geometry. Axle is designed to work with 50-65 mm long shocks with short travel. The axle uses a system of fully printed 3D Sets ball joints and is optimized for higher impact resistance.

- Truly functional 3D printed door handles – not for show, but prevent the door from opening while driving. Safety first!

- Preparation for the functional lights – the lights have prepared cavities for LED diodes, cable glands are prepared in the model.

- Highly detailed model of the engine – the engine covers the moving parts of the gearbox and it is possible to experiment with color by changing the filament during printing.

- Innovative battery box with easy opening with rotary locks, easily accessible from the bottom of the model.

- Many new details – e.g. realistic emboss on the inner parts of bodywork, interior trims, fuel tank in the trunk, and more.

- Modular Bodywork and parts – if you have Model 7: Buggy too, you can combine all parts together! Imagine creating an open-roof Buggy, or attach the bodywork Rear End with a proper Engine Hood. Or vice versa – build a Buggster with a sedan body! Engage your imagination and build your own variant.

What you get:

- 3d printing files: .stl and .gcode optimised for Prusa Mk2-3 and Prusa Mini printers, .stl for regular 3d printer with 20×20 cm bed size. The total download size is over 400 MB. Total printing time is about 10 days of continuous printing.

- step-by-step build guide, available here

- list of all non-printable items (like motor, tires, screws, etc.) with link to recommended online stores

What you will need:

- any 18 x 18 cm (or bigger) 3D printer, Prusa i3 recommended

- 3 kg of filament needed for all parts, PLA and PC Blend for some specific parts.

- bring your own motor/speed controller, servo, and battery

- screws and nuts

- set of bearings

- set of rubber tires and shocks

How I get the purchased files?

- after purchasing this digital product, you can download the printing files under “My Account” (in the “Downloads” section)

There are no reviews yet.