Max Team XL, part 5: Grand Finale!

13. 3. 2025

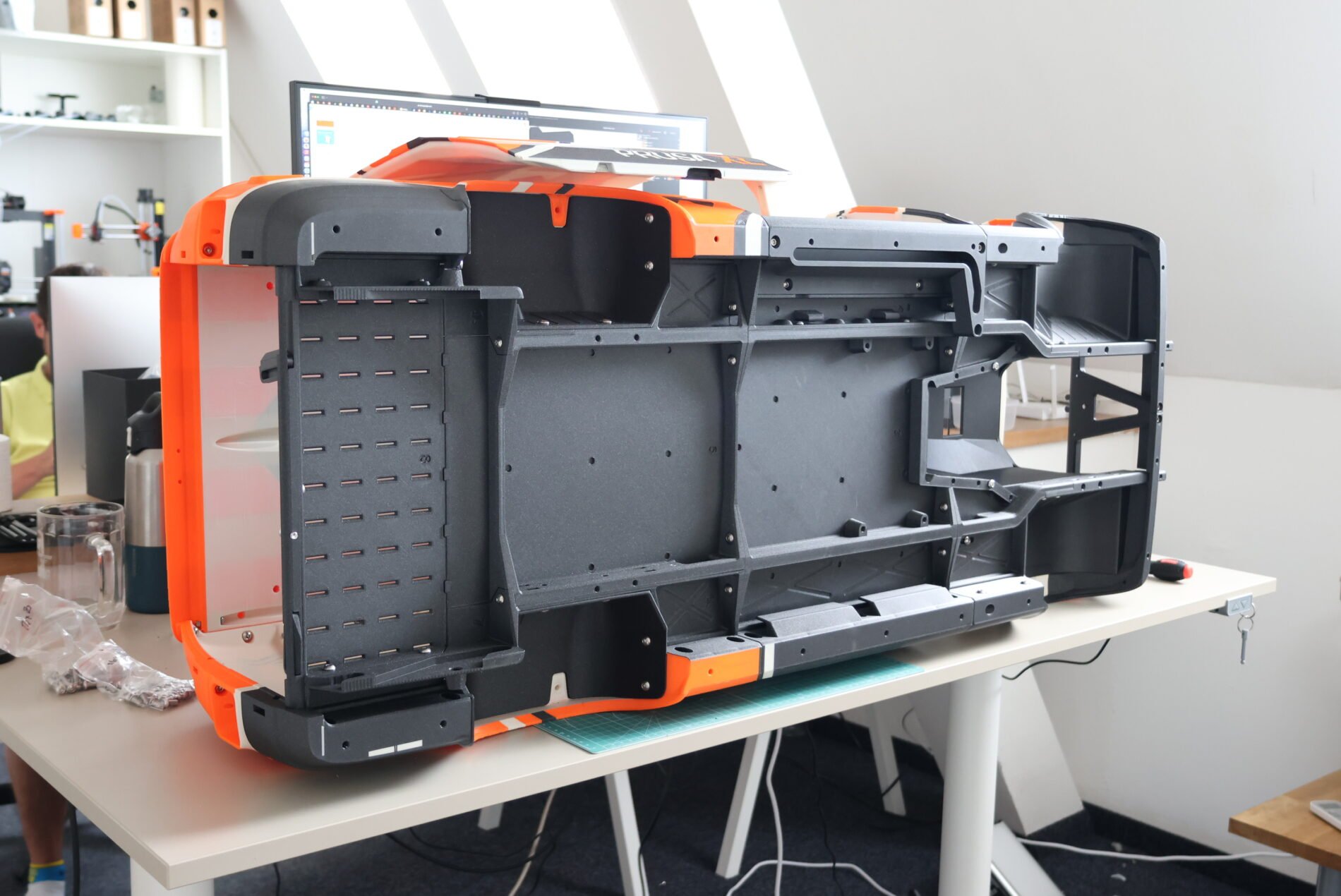

After many months of preparation, hundreds of hours of printing and intricate assembly, we have finally reached the moment we have all been looking forward to. Max Team XL in 1:4 scale is ready! How did it all turn out? Let’s recap.

Assembling the model was extremely challenging, mainly due to its size and weight. After assembling the main structural components, we fine-tuned the electronics, adjusted the suspension and tightened all 1 kg of fasteners. The result? The model is complete and ready for action!

The first test drive took place in our office, which is definitely not designed for testing RC cars of this size. So we just drove the car gently to make sure everything was working, and at the same time we didn’t break it right away.

What did we learn?

But now the main thing – to introduce Max Team XL to the world!

We took the model to our friends at Prusa Research, where we could finally show it to the public. And the reaction? Everyone was absolutely blown away by it!

To illustrate how big the car really is, we put a 1:8 scale Landy 4×4 Hardtop, which the guys from Prusa Research once printed themselves, into its cargo area – the contrast was incredible.

Of course, we couldn’t pass up the opportunity to photograph Max Team XL with the Original Prusa XL printer right in front of the iconic wall full of a variety of prints.

We then brought the model outside to shoot a short promo video. And it was here that the first real drive outside took place – the car experienced the terrain as well as the asphalt and made it through unharmed. The movement and reactions to the surface resemble a real car, which just underlines how close we got to reality with this model.

Finally, we moved on to the place that had been our clear goal from the beginning – the Prusa Research printing farm. Max Team XL took a ride among hundreds of printers, which was an absolutely epic ending to the whole project.

The resulting video beautifully sums up the whole Max Team XL adventure.

The whole project would not have been possible without the support of our friends at Prusa Research, who deserve a huge thank you for lending us the Original Prusa XL printer, providing us with Prusament filament and their overall support.

Their technology allowed us to turn a crazy idea into reality and create the largest model in the history of 3D Sets. What’s more, we had the opportunity to introduce Max Team XL right in their home environment, where it was a huge success.

Thank you!

The Max Team XL project was a huge challenge that brought not only a lot of learning but also unexpected moments. How can we sum it up in a nutshell?

The 1:4 scale Max Team XL is proof that 3D printing can do much more than one might think. It’s the biggest model we’ve ever built, but certainly not the last experiment. What do you think, should we go further? Maybe 1:2? Or even 1:1? 😁