Max Team XL, part 4: When 3D printed parts come together

14. 2. 2025

After hundreds of hours of printing, countless spools of filament swapped and dealing with unexpected complications in the production of individual parts, the time has finally come for what we have all been eagerly awaiting – the assembly of a giant Max Team XL in 1:4 scale. As it turned out, this step was not only exciting, but also much more challenging than it initially seemed.

It’s not easy to start assembling a car that weighs over 25 kg. Each part was a hefty piece of plastic in itself, and some were so large that they were difficult to handle even on a large table. During assembly, it turned out to be a two-man job to turn the car around while working – literally.

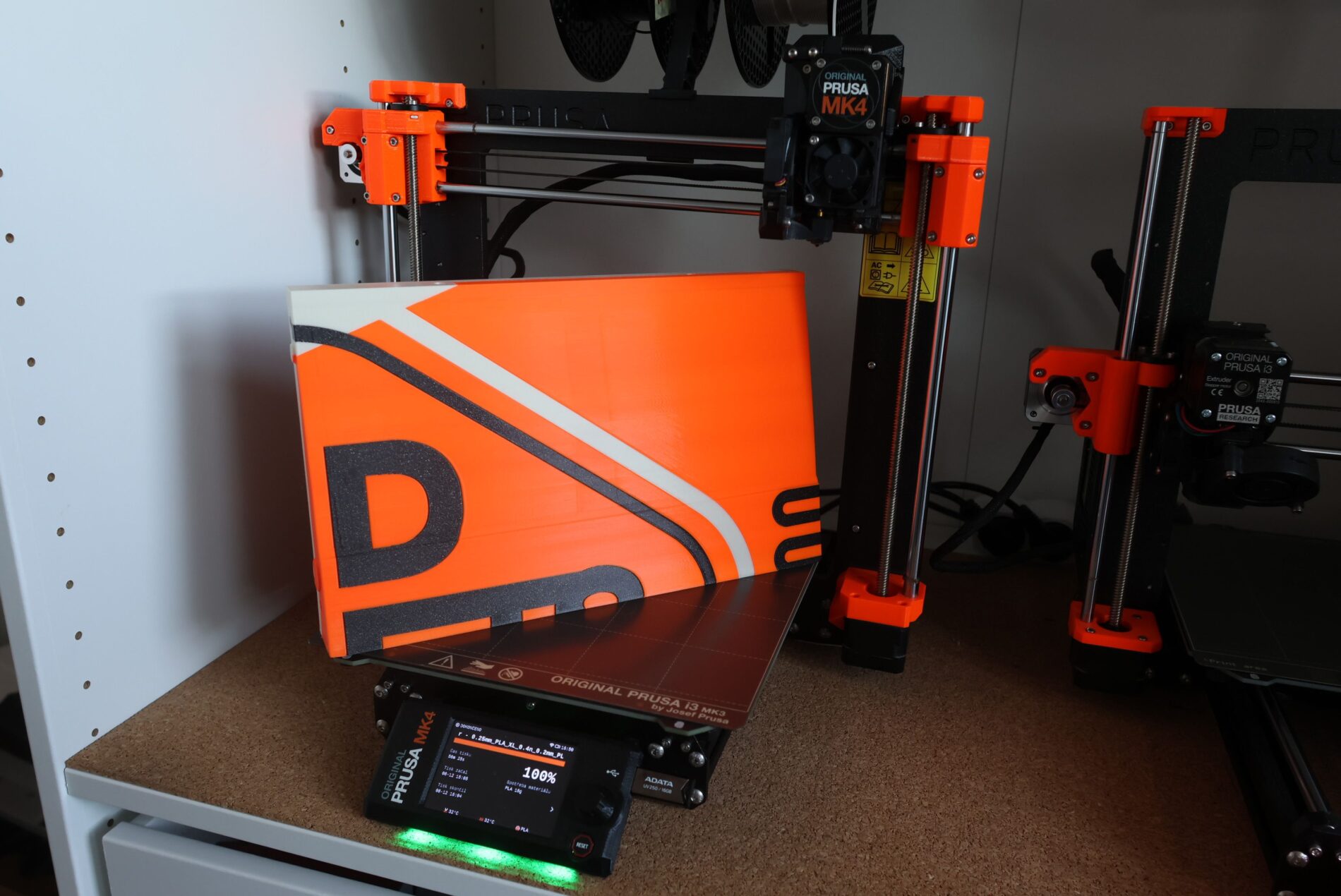

The biggest concern was the accuracy of the connections. At that size, it could easily happen that some parts would not fit exactly together due to minor inaccuracies or flexing of large parts. Fortunately, it turned out that despite the gigantic size, everything fit together perfectly. A big part of this is also due to the Original Prusa XL printer, which managed to print accurate and consistent parts without any major deformations. After months of preparation, this moment was incredibly satisfying.

However, what was the real surprise? The weight of the fasteners.

Every big project requires a lot of screws – that’s not news. But when we put them all together, they weighed over a kilogram! One kilogram in screws alone! Tightening them really did feel at times more like working on a real car than a 3D printed model.

One of the biggest challenges was finding a motor that had enough power to get such a colossus moving. This is where the project ran into an unexpected complication – finding a motor powerful enough that wasn’t huge and could still be mounted somehow proved to be a big problem.

In the end, Jirka decided to pull the motor out of his old RC boat, as it was no longer in production and could not be easily bought. It works, the car moves, but it’s clear that in the future a more powerful replacement will be needed to better match the weight of the model.

For steering, we used a servo with a pull of 72 kg, which is already a lot of power. However, in order to achieve full strength, it was powered via the UBEC by an external switched-mode power supply. Even so, turning the wheels is noticeably more strenuous than it would be on a smaller model, but for initial tests this setup is sufficient.

Although the build was more complicated than expected, first impressions of the complete model are amazing. The model is huge, heavy and incredibly impressive. When you look at it, you immediately realise what a huge difference there is between the standard 1:8 scale and this 1:4 version.

Now the final step is to bring the Max Team XL to life and test it in the field.

In the next (and final) part of this series, we’ll take a look at the first run, final tuning, and overall project summary. And of course – we’ll show you Max Team XL in all its glory!

So, are you curious to see the result? We certainly are! 🚗💨